01 December 2016

Genairclean success

In 2012 we received a £300k grant from the Technology Strategy Board to help us research and develop our Genairclean microbubble membrane cleaning technique and products. This enabled us to buy and install new state-of-the art lab equipment and our own reverse osmosis pilot plant so we could perfect the system.

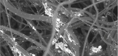

This year Asif Sheikh, Stephane Jarrige and Matt Armstrong have really championed this innovative cleaning technology, with outstanding success cleaning plants that were heavily fouled with clay or bacteria and other organics.

The approach combines numerous different cleaning mechanisms and chemicals, including osmotic backwash, effervescing reagents, microbubbles, detergents, surfactants and chelating agents. This results in a more effective clean in a fraction of the time needed for conventional cleaning.

The technique has recently been applied with great success at chemical plants, refineries and a very large saltwater reverse osmosis plant affected by algal blooms.

This year Asif Sheikh, Stephane Jarrige and Matt Armstrong have really championed this innovative cleaning technology, with outstanding success cleaning plants that were heavily fouled with clay or bacteria and other organics.

The approach combines numerous different cleaning mechanisms and chemicals, including osmotic backwash, effervescing reagents, microbubbles, detergents, surfactants and chelating agents. This results in a more effective clean in a fraction of the time needed for conventional cleaning.

The technique has recently been applied with great success at chemical plants, refineries and a very large saltwater reverse osmosis plant affected by algal blooms.