03 May 2017

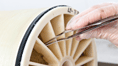

Genairclean – the power of microbubbles

Asif has conducted five Genairclean cleans in the last four months, with excellent results. Here are some examples:

SITE 1 – US EAST COAST

This 9,000 m3/day two-stage RO plant consists of three trains of eight pressure vessels. The plant is fed with well water with high silica levels of 60-70mg/l. Historically cleans were conducted six times per year to tackle microbiological and silica fouling. Conventional liquid acid and alkaline cleaners had been used since the plant was established but it had become increasingly difficult to remove silica scale and improve membrane performance without repeating cleaning steps, which took six to eight hours per train.

Using Genairclean, performance was restored in just two hours. Four times the usual amount of silica was removed and the dirty cleaning solution was clear proof of the improved removal of other deposits.

SITE 2 – TURKEY

This 10,500 m3/day BWRO plant was suffering from increased differential pressure and reduced permeate flow on the first stage due to clay and suspected biofouling on the lead elements.

Following cleaning using the Genairclean system, differential pressure was reduced by 26% and permeate flow increased by 15%. This was a vast improvement on previous cleaning attempts.

SITE 3 – SURINAME

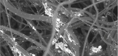

This 1,836 m3/day BWRO plant was suffering from severe biological and iron and manganese fouling. Despite cleans being carried out every two months there was rapid refouling and high differential pressure, which resulted in spacer protrusion and damage to the membranes. Some elements even needed replacing after less than a year.

After cleaning with the Genairclean system, the differential pressure decreased from 7.9 to 3.8 bar and permeate flow was restored to the design parameter of 50 m3/hr, while maintaining 99.5% salt rejection. The colour of the spent cleaning solution demonstrated the effectiveness of the technique for removing biofouling, iron and manganese.